400Hz-Ground-Power-Unit

Add in inquiryType:

IGBT / PWM Type

Capacity:

- Single Phase: 1~80KVA

- Three Phase :

10~60KVA, 80~160KVA,

200~400KVA, 500~1,000KVA

Made in:

Taiwan, ROC

Add in inquiryType:

IGBT / PWM Type

Capacity:

- Single Phase: 1~80KVA

- Three Phase :

10~60KVA, 80~160KVA,

200~400KVA, 500~1,000KVA

Made in:

Taiwan, ROC

• MILITARY APPLICATIONS:

• ⇒ Military Program, Shipboard, Submarine

• ⇒ Aircraft, Mobile Power Units, Shelters

• ⇒ Military System Diagnostics

• ⇒ Military Research & Defense Weapons

• Airport Grounding Facilities include

• Airport Terminal, Control Tower

• Navigation

• Shore Power Supply

• Voltage and / or Frequency Conversion

• Power Conditioning & Freq. Stabilization

• Communication Systems

• Export Product Testing

• Precise Measuring & Testing Equipment

• Transportation Signaling Power

• TV & Radio Broadcasting Stations

• Any Facilities / Instruments have

• 400Hz frequency Power System

USA Military Approved Power System !

► FULL DIGITAL AND INTELLIGENT AC VOLTAGE / FREQUENCY CONVERTER (CVCF)

► USA MILITARY APPROVED

Through OEM or ODM for some USA makers, the SPM series have been used by USA Airforce, USA Army, USA Navy, NASA, Boeing, USA aircraft manufacturers, airliners … etc.

► 400HZ INPUT / OUTPUT FREQUENCY AVAILABLE OPTIONS TO MEET MILITARY SPEC.

Precise frequency (oscillated by crystal oscillator). Designed for application of Airforce, Military, Navy, Aviation, Aerospace, Shipboard, Navigation ... etc.

► POWER CONDITIONING & FREQUENCY STABILIZATION

The SPM series provides clean and stable, regulate power to the load, and the chosen crystal oscillator controlled frequency, free from any spikes, surges, lightning and frequency fluctuation.

► HIGH EFFICIENCY, OPTIMUM STABILITY, AND SUPERIOR HEAT DISSIPATION

By use of advanced technology DPS, IGBT and Switching Components to increase the reliability, efficiency and heat dissipation

► COMPLETE INPUT TO OUTPUT TRUE GALVANIC ISOLATION DESIGN

Solve ultimately power problems, including noise, lightning, ground leakage current, and CEMF (Counter-electromotive Force) etc.

► RELIABLE INPUT PROTECTION

Circuit breakers are placed in each individual input loop to ensure power can continuous through another loop in case of breaker trip caused by an abnormal condition.

► INPUT SURGE PROTECTION

MOV (Surge Protectors) are added at the input, providing sufficient protection to both the unit and the load from any ligntning or surge caused by neighboring large loads.

► EMI SUPPRESSION

An EMI Filter is fitted to meet the international EMI limits. Therefore, very low noise is emitted, to prevent interference to other equipment connected to the same AC source.

► RUGGEDNESS

The rectifiers employ phase control technology to regulate the DC bus voltage. SCRs are employed as rectifiers to take advantage of their ruggedness under poor conditions. In addition, inductors are used at the input to avoid deforming the AC source waveform.

► ±20% WIDE INPUT VOLTAGE RANGE

The SPM series is designed to accept a wide input range, it can work effectively under any unstable AC source. All of the input components used are specially selected to handle extremely high voltage and high current.

► MULTI-CPU DESIGN AND SOFTWARE / HARDWARE COOPERATE CONTROL

Several CPUs are employed in the control circuit, critical functions are designed to parallel redundancy to improve reliability.

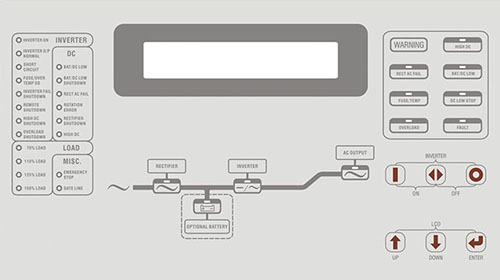

► DIAGNOSTIC PANEL WITH LCD AND LED DISPLAY

• LCD display Real time status, data or historical events and parameter settings.

• 24 Status LEDs represent all of the up to date information for clear and in time troubleshooting.

► MODULAR DESIGN PCB WITH COLOR MANAGEMENT INDICATORS

All PCBs are Modular design and integrate inside the PCB Holder. In case the SPM series were failed, open the holder, visual inspect the indicator color with beneath descriptions for easily find faults and replace the PCBs at once.

► PLUG & PLAY MODULAR DESIGN FOR QUICK MAINTENANCE AND TROUBLESHOOTING

The power circuit is separated into several modules plugged into several slots in the unit, which are easy to pull out, permitting quick maintenance and easier troubleshooting (MTTR < 25minutes).

► TOLERATE HARSH ENVIRONMENT

Each component is chosen with large safety margin to accommodate Extreme environments, such as temperature, humidity, altitude, shock or Contamination.

► EACH PHASE WITH INDIVIDUAL INVERTER SUPPORTING

Characteristics will not be violated under 100% unbalance load.

► BASE WITH ANCHOR BOLT FIXING

The floor loading capacity should be high enough to endure the weight of the SPM series.

The SPM series is mounted on four right-angled steel angles. Insert corresponding bolts and nuts 2 (dia. 1/2") into the floor for securing the SPM series on the floor when it is located in an area where earthquakes is possible, or where motion may occur, e.g. vehicle mounted.

► INTELLIGENT FAN ROTATION RATE CONTROL

The fan rotation rate can automatically change according to the load condition, so that the fan’s life expectancy is extended and audible noise is reduced.

► REASONABLE HEAT EVACUATION PASSAGE DESIGN

Control circuitry and power circuitry are physically separated. Thus, the SPM series can operate under harsh environment.

► CUSTOMIZATION WELCOME

Please contact us, we will welcome the opportunity to review your problems and provide you with necessary solutions.

► BATTERY ADDED FOR UPS BACKUP (OPTION)

• 3 PHASE INPUT 3 PHASE OUTPUT, 10 ~ 1,000 KVA

• 3 PHASE INPUT 1 PHASE OUTPUT, 10 ~ 160 KVA

• 1 PHASE INPUT 1 PHASE OUTPUT, 10 ~ 60 KVA

• 1 PHASE INPUT 3 PHASG OUTPUT, 10 ~ 80 KVA

OTHER OPTIONS

► Customizations Welcome

► Custom input and output voltages and frequencies

► 50Hz / 60Hz Output Frequency Selectable

► Output Frequency Adjustable

► 10% Output Voltage Adjustable

► Single and Three Phase Configurations

► 400Hz Input and / or Output Frequency

► BATTERY can be added for UPS Capability

The SPM series can be started without an AC source, that is, can be started with battery power only. This is possible because current limit circuitry is added, preventing the problem of large inrush current from blowing the battery fuse and damaging the DC capacitors when batteries are connected to an empty DC bus (before the DC bus is energized).

► INPUT HARMONIC FILTER

► SERIAL & PARALLEL REDUNDANT CONNECTION

A supplemental power supply is added to provide redundancy for supplying power to the static switch, so that there will be AC output no matter what happens to the Frequency Converter.

► 12-PULSE FULL CONTROLLED RECTIFIER

Reduce harmonic current for 80KVA and above SPM series.

► EMERGENCY STOP SWITCH

Be installed outside or nearby the Frequency Converters for stopping the Frequency Converters output in case of emergency.

► SHOCK MOUNT

The cabinet can be shock mounted using optional rubber or coil type isolators. This will enable the unit to withstand shock levels as specified in MIL-S-901.

► CASTERS & LEVELERS

For portability, the cabinets may be optionally equipped with the base-mounted caster / leveler set as shown.

► CABLE ENTRANCE DIRECTION

Cable entry can be from Front, Side, Rear or Top side

COMMUNICATIONS OPTIONS

► UPSCANTM - Remote Control Panel

A hand held remote display and control module with LCD and LED display that can monitor up to 99 Frequency Converters via RS-485 at a remote distance up to <1,000M (up to 3,000feet)

► GPRS MODEM - Auto-dialing Module

In case of abnormal situation, it will automatically dial to specified service center for help. Multiple phone numbers can be set and no dedicated line is required.

► UPSCOMTM - 3 Phase PC Monitoring Software

Can provide real-time three phases information of Frequency Converter connected on the line and monitor 31 Frequency Converters max. with one PC.

► 3 Phase SNMP Card

Can monitor and manage the Frequency Converters through Web browser and Java applet, providing simultaneously three phases data acquisition.

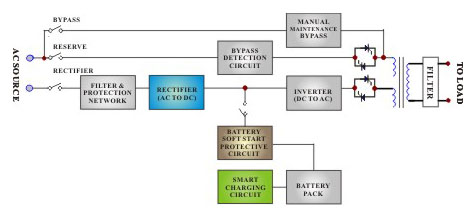

INTRODUCTION

Static Frequency Converter :

The static frequency converter used semiconductors to rectify AC source power at source frequency and voltage into DC power before using an inverter to generate a new AC power at the required frequency and voltage from the DC power. There are no moving parts except for some cooling fans in the converter.

Key features are :

1. The input and output are isolated via isolation transformer

2. The output voltage regulation can be stable up to 0.2%

3. The output frequency can be very stable up to 0.01Hz

4. The output voltage and frequency can be variable to suit testing purposes

5. Suitable for indoor application with air-conditioned ambience

6. Compact in size which save space for installation

WHY DO YOU HAVE TO CHOOSE STATIC FREQUENCY CONVERTER INSTEAD OF ROTARY FREQUENCY CONVERTER?

1) RELIABILITY :

Unlike rotary generator sets, Static frequency converters have no moving parts to wear out or break. The result is higher dependability, longer MTBF, and shorter MTTR.

2) MAINTENANCE COSTS :

Those moving parts in the rotary generator sets have to be serviced and maintained on a regular basis, or the risk of premature failure increases even further. Static converters require no such maintenance, dramatically reducing the cost of the converter over its useful life.

3) NOISE :

Since Static converters have no moving mechanical parts generating a loud racket, the only sounds heard from the unit come from the small cooling fans and the transformer.

The result is very quiet operation ? Typically 55 dBA at 1meter distance.

4) SIZE:

Typically, Static converters of any given power output ratings are much smaller and lighter than rotary generator sets of the same power output rating.